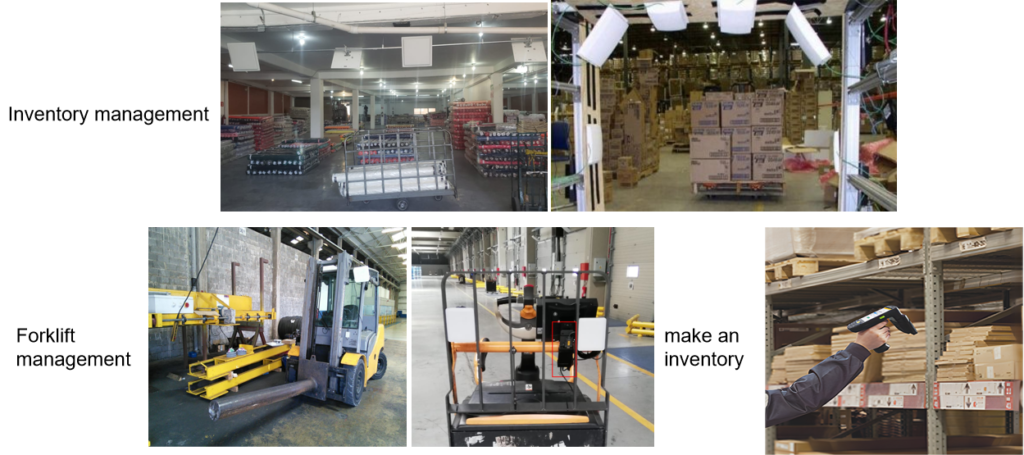

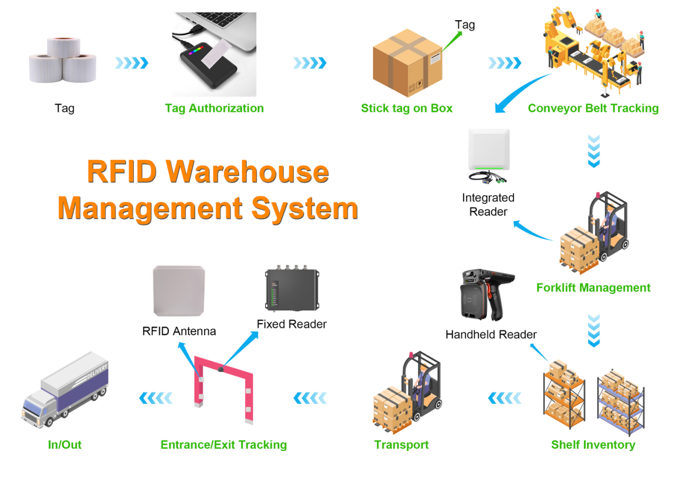

Under the existing warehouse management, warehouse management system introduces RFID technology to collect the data automately of various operational aspects such as Arrival Inspection, Inbound, Outbound, Redeployment, transfer to different location, Stock Inventory, etc.

1、Brief description of the program

2、Tag authorization and paste

With UHF reader writer will read the tag number into the software system, the tag number in the system and the goods information corresponding to the binding, such as the need to give the tag a special number, you can also use the reader writer to write first.

3、Warehouse access management

Use UHF multi-channel fixed reader to connect the UHF antenna to be installed on both sides or top of the warehouse entrance. UHF tagged items are recognized when they pass through an entrance or exit, and the data can be sent remotely to a server.

4、Inventory management related equipment

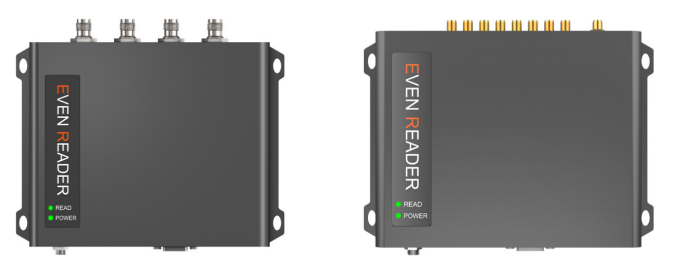

Fixed Reader CF815 four-channel & CF816 eight-channel

- Communication interface RS232, USB, RJ45, customizable POE

Antenna CF-RA5001 & CF-RA9002 & CF-RA1201

5、Shelf stock inventory

Regular inventory of clothing on shelves and in storage areas requires the use of UHF handheld reader or UHF Bluetooth back clips with group read capability and fast tag recognition over long distances.

H105(Handheld Reader) & H103 Bluetooth Back Clip

6、Forklift management

The use of forklift trucks for cargo transfer, the use of rfid technology to monitor the working status of forklift trucks can be broadly categorized into two situations: single tag identification and multi-tag identification.

Single tag Recognition:Forklift once to transfer a board of goods, this board of goods only a tag needs to be identified, that in the front of the forklift installation of UHF integrated reader can be, when the forklift forklift loaded with goods on the board, the tag has also entered the integrated reader identification range of the integrated reader to read the tag data and uploaded to the management system.

Multi-tag recognition:Forklift transfer a cardboard of goods at a time, there are more than one tag needs to be recognized, then use UHF fixed reader to connect more than two UHF antennas, install the antenna to the front of the forklift, when the forklift forklift on the cardboard of the loaded goods, the tags on the goods into the recognition range, the rfid tags on the goods are read, the fixed reader through the network port or serial port or WiFi communication will be read to upload the tag data to the management system.

7、Forklift management related equipment

(1)Integrated reader CF6A1

8、RFID tags for warehouse management

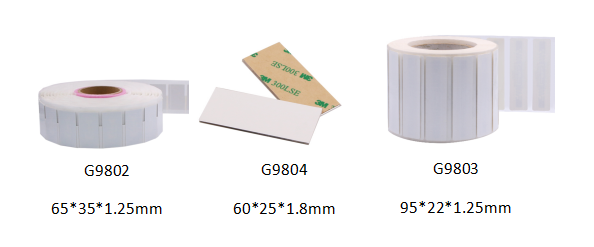

Our rfid tags commonly used UHF chips are U8, U9, H3, etc., roughly divided into 3 categories: paper tags, anti metal tags, flexible anti-metal tags.

If the management of goods is non-metallic cartons, plastic boxes, etc., can be used ordinary UHF paper tags.

- UHF paper tags are available in different sizes and can be customized to special sizes.

- The material of the tag is PP synthetic paper, if you need PET can also be done.

UHF Paper tags G9201

9、RFID tags for warehouse management

If the goods to be managed are metal machines, tools, etc., then UHF hard anti-metal tags can be used. Material ABS/PCB/Specialty materials Waterproof, high temperature and corrosion resistant Screw holes with backing tape

UHF Anti Metal tags

Flexible Anti-Metal tags are used when metal items are managed in such a way that they need to be taged on irregular surfaces. Made of special electronic material + AL

UHF Flexible Anti-Metal tags

10、Application scenarios